Extraction Systems

Virtually all laser operation whether engraving, marking or cutting will give off different levels of smoke and fume depending on material being converted. It is a vital that these elements are removed in an efficient and safe manner to avoid poor quality cutting, potential corrosion of machine parts and danger to the operator.

What is fume?

As the laser thermally decomposes the substrate it gives off fume which is a mixture of particulate and gaseous matter. Fume from materials such as metals and glass are mainly particulate, the majority of which is less than 5µ (microns) in diameter. Organic materials, particularly plastics, produce much more complex fumes which require a greater level of extraction. Most of the particles are spherical and roughly 90% by weight are less than 1µ in diameter. These particles fall within the respirable range and need to be removed from the working environment to prevent bronchial or lung damage. These gaseous organic compounds produced are known as Volatile Organic Compounds, VOC's.

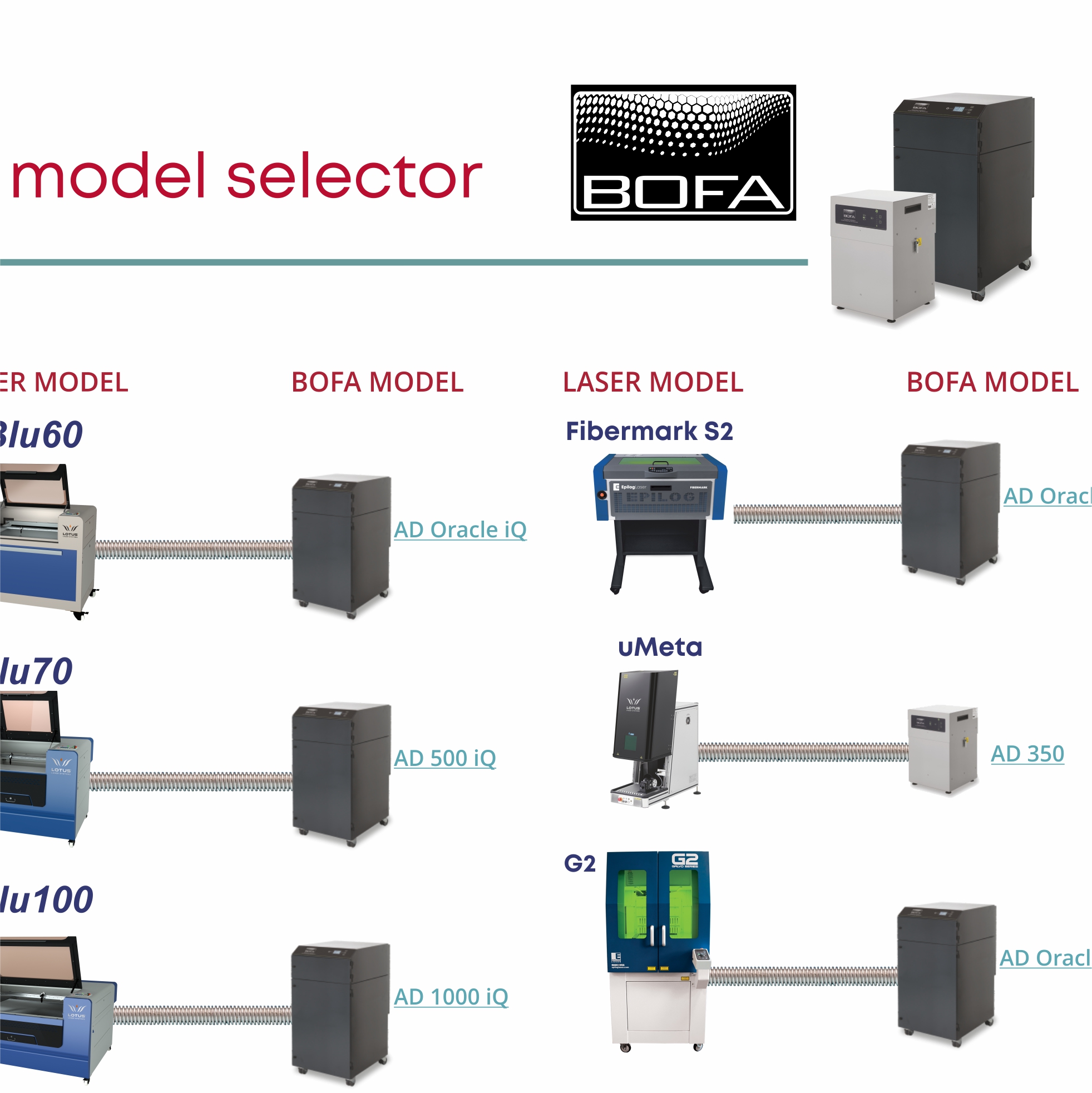

BOFA Model Selector

BOFA Model Selector

The most efficient way to remove fume is by connecting a fully filtered extraction system to the exhaust ports/s on the laser. This system intakes the dust and fume from the laser cabinet, feeds it through a series of filters and then expels clean, recycled air back into the environment. The filters are replaced periodically as they fill up. Each laser has a manufacturer recommended air flow rating expressed as CFM (cubic feet per minute) or L/m3s (litres per second) this will vary according to the size of the work area (cabinet) on your laser.

EUR (€)

EUR (€)